When safe mechanical design is not enough

In order for modern and innovative equipment that facilitates production processes to be safe for its operator to use, the design of the equipment automation system must be safe and thoughtful. The EU Machinery Directive recommends following the ISO 13849-1 standard.

What is the 13849-1 standard?

The ISO 13849-1 standard describes safe and proven design solutions for control system safety functions. The recommendations specified in ISO 13849-1 can be considered as minimum requirements for the development of control system safety units, so that the equipment can be marked with the "CE" mark. ISO 13849-1 describes and applies to any type of motion transmission, regardless of its technological nature or origin (electrical, hydraulic, pneumatic, mechanical). The technical documentation, which is developed and compiled according to ISO 13849-1, is mandatory and must be added to the technical file of the equipment when it is put on the market.

As very simple examples, we can mention the installation of an emergency "stop" button on the machine, or a safety gate, after opening which the machine should stop. Such functions are considered safety functions for the equipment, and their performance (safety level) must be analyzed according to the ISO 13849-1 diagram, and technical documentation must be prepared to prove their performance.

As a slightly more complicated safety function, we can mention the case where a "PLC" is used to implement a safety function, for example, the direction of rotation of an electric motor is monitored. According to the ISO 13849-1 standard, it is necessary to perform not only the performance analysis of the electrical unit, but also to prepare a technical file for the "PLC" program, which describes and proves the safety performance of the program.

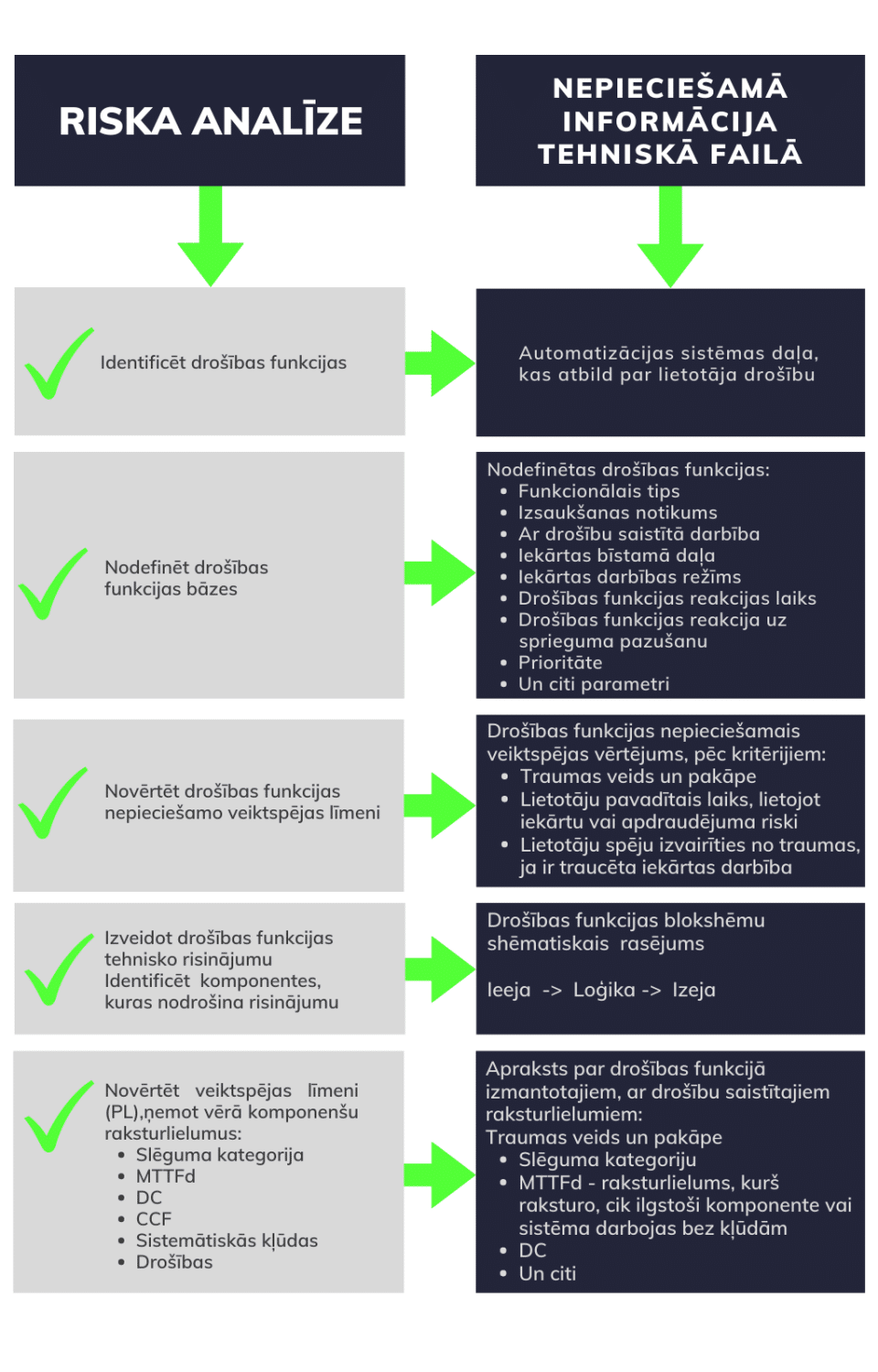

ISO 13849-1 block diagram and necessary information in the technical file: