IMPROVE PRODUCTION EFFICIENCY

INDUSTRIAL DATA

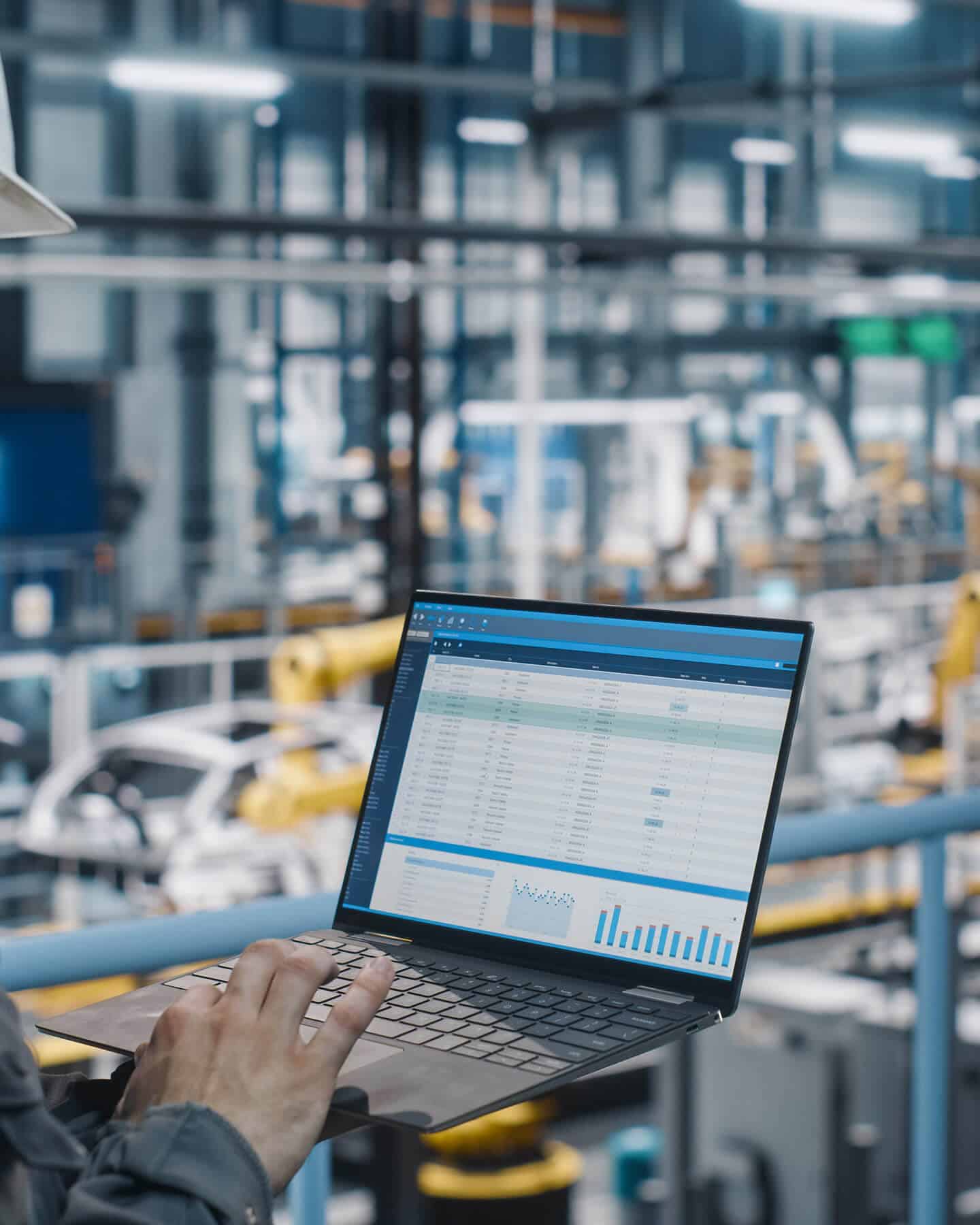

Our comprehensive industrial data solutions include secure integration of data points, thorough processing and intuitive visualization of all data points related to production and technology operations. By offering a robust platform for the seamless integration of operational technology (OT) and information technology (IT) systems, we enable companies to optimize manufacturing processes with unprecedented efficiency.

In today's competitive environment, tracking the production process is not only beneficial, it is mandatory. Companies need to closely monitor every aspect of their production line to identify inefficiencies, streamline workflows, and improve overall productivity.

With our industrial data solutions, you can gain invaluable insights into your manufacturing operations to help you make data-driven decisions that drive growth and innovation. From identifying bottlenecks to predicting equipment maintenance needs.

Through real-time data analysis and visualization, companies can proactively solve problems, reduce downtime and maximize production. Ultimately, our services enable businesses to achieve operational excellence, reduce costs and deliver unmatched value

IAS INDUSTRIAL DATA

SERVICES OFFERED

All about

FOR INDUSTRIAL DATA

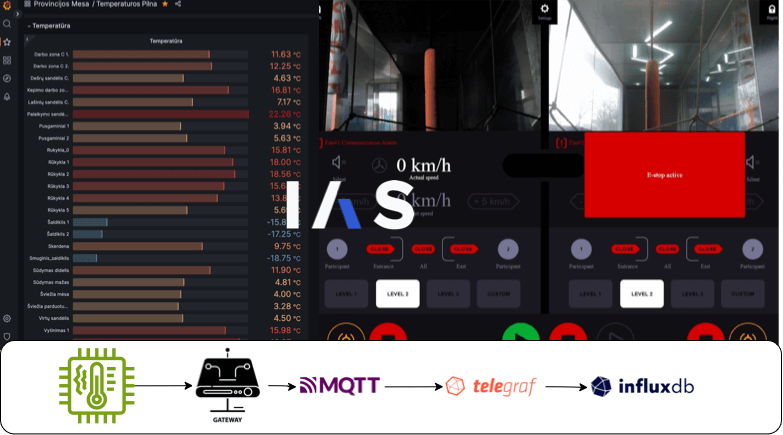

Industrial Data Analytics Awakening: Leveraging Open Source Technologies for the IoT

The Importance of Industrial IoT Data Analytics

Useful

IAS ARTICLES

Electromagnetic compatibility aspect of functional safety - ISO 13849-1: 2023

The latest functional safety standard ISO 13849-1:2023 Safety of machinery — Safety-related parts of control systems — Part 1: General design principles, includes electromagnetic

Industrial Data Analytics Awakening: Leveraging Open Source Technologies for the IoT

In the ever-changing landscape of Industrial Internet of Things (IIoT) data analytics, companies are constantly looking for innovative solutions to unlock the full potential of their data. At IAS, we specialize in IIoT data

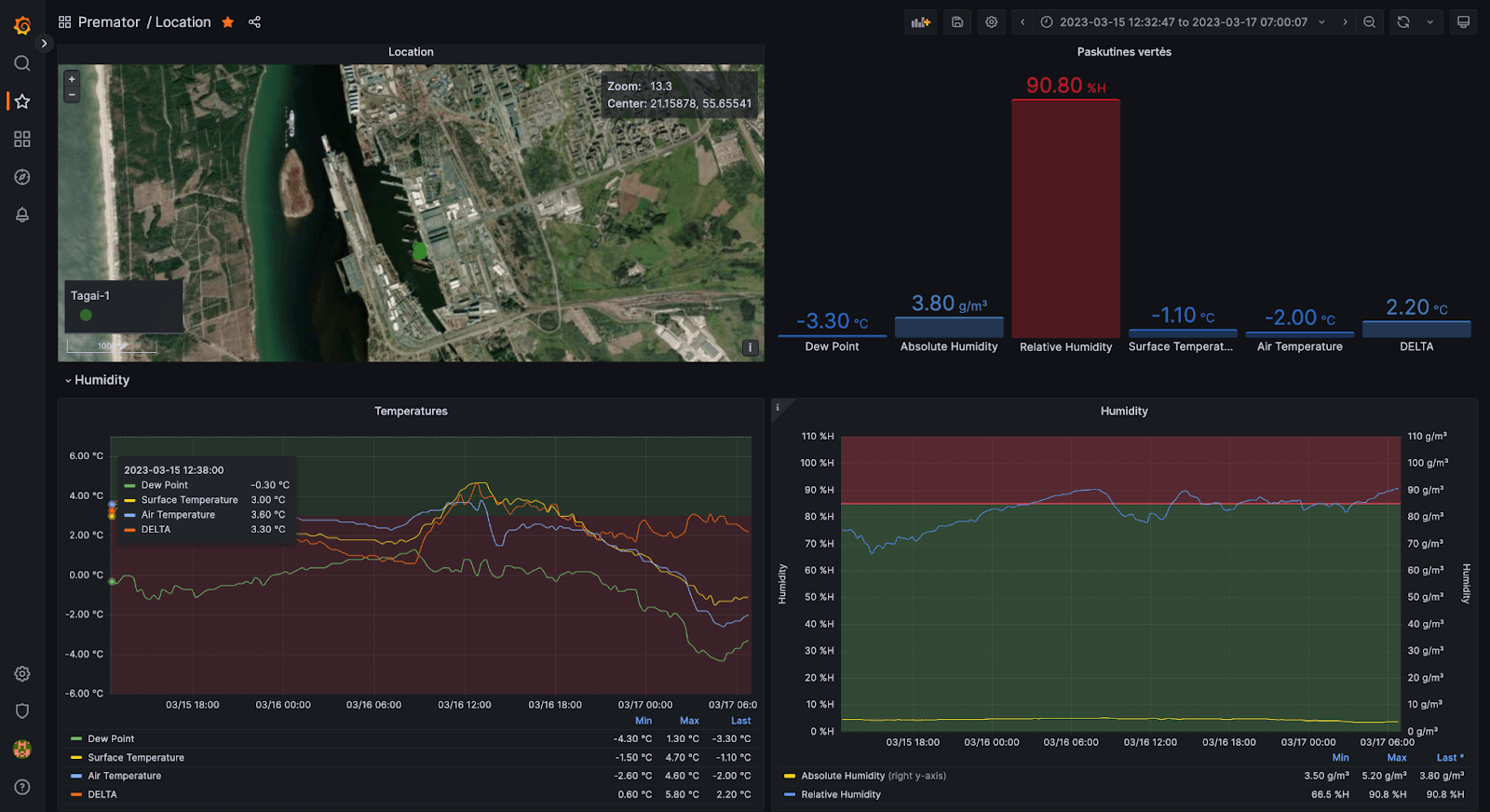

The Importance of Industrial IoT Data Analytics

Today, manufacturing plants are equipped with numerous sensors, actuators, and interconnected devices collectively known as the Industrial Internet of Things (IoT). These smart technologies generate